About RONO

Customized process solutions and proven technology made to order.

We manufacture individually, quickly and flexibly and always according to the latest state of the art.

Highest quality demands and customer-oriented behavior are our guiding principles.

RONO History

A company rich in tradition

Rono was founded in April 2005 due to the restructuring process and closure of the GerstenbergSchröder production facility in Lübeck. We took the chance to continue the production business in Luebeck using the Know-how and experience of the existing team and founded this new company.

Nearly all former “Schroeder-Colleagues” agreed to the fresh start with RONO.

Only this enabled us from the beginning to deliver high qualified products for the food industry within a very short time.

Margarine Cooler from 1957

Ancient lathe from 1964

WIG welder around 1976

RONO Today

Experience and know-how for your projects

Our workforce consists of 80 experienced craftsman, technicians and engineers, specialized in various technologies. We are a team of skilled design engineers, well organized order handling and highly trained production staff. Our comprehensive know-how in our team of engineers, process colleagues and food technologists enables us to supply complete process solutions for our customers.

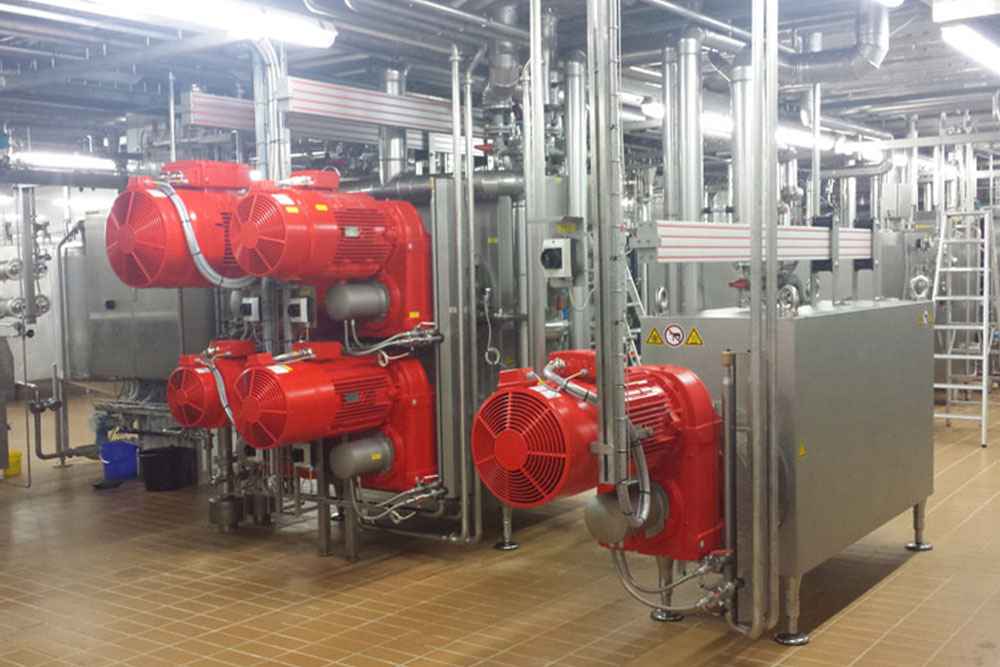

New office & production facility 2014

Modern part production

View into the assembly

Facts about RONO

MORE THAN

0 m²

PRODUCTION AREA

CUSTOMERS IN MORE THAN

0

COUNTRIES WORLDWIDE

CONFIRMED

0

CUSTOMER SATISFACTION

MORE THAN

0

EMPLOYEES

Unlimited

∞

integrated solutions

Our industry expertise

Manufacturing of scraped surface heat exchanger, pinworker, emulsifying systems and batch

processing is the business we are coming from and we are proud to look back to a long tradition.

Our continuous development of RONO technology and the permanent dialogue with our customers

enables tailor-made and innovative solutions for process plants in the food industry.

RONO TECHNOLOGY

RONO is a specialist in process solutions for the food industry and with many years of experience.

Our process plants are multifunctional, highly flexible and are always designed individually according to customer specifications to the desired end product.

Possible applications of our RONO Technology are:

Storage, provision and supply of raw materials

Preparation, mixing and assembling of all individual phases

Pasteurizing, tempering and cooling

Dispersing, homogenizing or emulsifying

Crystallizing, texturing and consistency improvement

Continuous process or batch systems

Depending on the desired production capacity, the final food product and herewith the required process steps for your quality product, RONO will choose the best technology for you.

Continuous production of margarine & spreads

Continuous treatment of butter products and production of recombined Butter

Continuous production of pastry margarine, bakery products & industrial fats

Continuous high pressure pasteurization and continuous rework systems

Batch Systems for mixing and cooking of vegetables, soups, stews & convenience foods

Batch Systems for mayonnaise, ketchup, sauces, dips & dressings

Continuous emulsifying systems for fine food products

RONO Pilotplant

In collaboration with technical universities and training centers for food technology, the RONO team of technicians, process engineers and food technologists has developed a very complex and versatile usable continuous pilot plant, design for 50 to 100 bar working pressure. Due to the modular system, all machines, aggregates and control components can be combined individually to match customers demand to an innovative test facility.

Tailor-made solutions - There are no wishes left open